[羅戈導讀]無人貨架真的是偽命題,小商店到處都是模式太重,營收太少。零售要解決的根本不是前端的問題,零售要解決的真正是供應(yīng)鏈和貨品質(zhì)量的問題,無人貨架在未來的某個時間會以另外一種方式回歸。

[羅戈導讀]無人貨架真的是偽命題,小商店到處都是模式太重,營收太少。零售要解決的根本不是前端的問題,零售要解決的真正是供應(yīng)鏈和貨品質(zhì)量的問題,無人貨架在未來的某個時間會以另外一種方式回歸。

無人貨架真的是偽命題,小商店到處都是模式太重,營收太少。零售要解決的根本不是前端的問題,零售要解決的真正是供應(yīng)鏈和貨品質(zhì)量的問題,無人貨架在未來的某個時間會以另外一種方式回歸。即使現(xiàn)在,也在硬件上不斷迭代降低成本。因為購物越來越“服務(wù)化”,無人就符合服務(wù)體驗。

蛤蟆集團認為無人貨架這個模式無任何機會可言。工作場景的這種需求會由企業(yè)園區(qū)便利店完成,企業(yè)園區(qū)便利店會演變成線上+線下的新零售模式,導購可以提升一家零售店的60%以上的銷售,無人售賣機 將會替代無人貨架,蘇寧小店我一直特別看好。

蛤蟆集團覺得包括無人貨架、無人售賣機器之類的東西都沒戲。很簡單,只要從市場規(guī)模/真?zhèn)涡枨?盈利模式/護城河四個角度分析即可。名創(chuàng)優(yōu)品和優(yōu)衣庫、無印良品,他們有啥服務(wù),開街鋪好的很。后端是每個成功企業(yè)都一定要非常優(yōu)秀的,但是需不需要工廠則未必。只要供應(yīng)鏈管理的好,不需要工廠。

人工越來越貴,隨著無人貨架的成本從2萬降低到3000,供應(yīng)鏈管理的效率提升,很多場景就會改變。無人貨架上架的都是保質(zhì)期長的垃圾食品,而這種垃圾食品的味道真的不好。無人貨架頻繁的送貨到貨架,運營成本太高倉儲成本高,要在一個城市隨時補貨,需要很高的倉儲成本,辦公室的消費環(huán)境有問題,大公司有自己零食區(qū),很多公司上班不能吃零食,公司樓下各種便利店,貨架太小,可挑選目標太少1、喜歡吃零食的都會覺得零食味道好。2、無人貨架不用頻繁送貨,一天補1-2次即可。3、倉儲如果是個問題,可口可樂不用活了,可口可樂要給每個便利店補貨的。4、建議去看看其他公司,95%以上的辦公室沒有零食區(qū)。

從需求端來看,傳統(tǒng)的零售三角模型,是滿足消費者多選/便利/廉價的需求,無人貨架之類的模式,很顯然是為了滿足其中單一要素即“便利”,僅此而已。那么就要判斷,這個便利是不是公司場景的真實需求,或者說,消費者會不會因為便利這個單一要素,愿意接受“略高的價格”(一般都會比便利店貴些)、“較遠的生產(chǎn)日期”(這個是最尷尬的)、“差異化定位的產(chǎn)品”(為提升毛利選擇的非普通大眾常見品)…

從經(jīng)營角度來看,無人貨架系列產(chǎn)品盈利模型非常不清晰,包括貨品丟失/臨期產(chǎn)品處理/上架下架管理等一系列涉及供應(yīng)鏈整個環(huán)節(jié)諸多問題無法解決;

毫無護城河可言。這就更不用說了。

好了不墨跡這個問題了,直接本我們的Kanban材料!

topics主題

Section 1: What is Kanban?什么是看板?

Section 2: Two-card Kanban Systems 2張看板卡系統(tǒng)

Section 3: Kanban Calculation 看板的計算

我們這一期講這些:

Section 4: Managing the Kanban System 管理看板系統(tǒng)

Section 5: Kanban System Implementation 看板系統(tǒng)的實施

-------------------------------------------------------------------------------Section 4: Managing the Kanban System 管理看板系統(tǒng)

The 6 prerequisites 6個必要條件

The 6 golden rules 6條金科玉律

Kanban circulation steps 看板循環(huán)步驟

Integration with the planning system與計劃系統(tǒng)進行整合

What Does it Mean to Manage the Kanban System?這對管理看板系統(tǒng)的意義?

Implement the 6 Prerequisites first 首先實施6個必要條件

Build a foundation of stability demand創(chuàng)造一個需求平穩(wěn)的基礎(chǔ)

Build process capability and responsiveness創(chuàng)造制程能力及應(yīng)答

Follow the 6 Golden Rules 按照6條金科玉律

Train and practice until it becomes second nature培訓及練習直到成為第2個本性

Material conveyance system supports the pull system物料勻速系統(tǒng)支持拉動系統(tǒng)

Integrate with the planning system與計劃系統(tǒng)進行整合

Responsibility for add / removal of cards based on demand and capability changes負責根據(jù)需求及產(chǎn)能的變更來增加或減少看板卡

The kanban cards replace other paper instructions the system must fail if kanban cards go missing看板卡替代其他的紙質(zhì)指示當看板卡丟失時系統(tǒng)一定會失效。

The 6 Prerequisites of Kanban Systems看板系統(tǒng)的6個必要條件Stable and predictable demand平穩(wěn)及可預測的需求

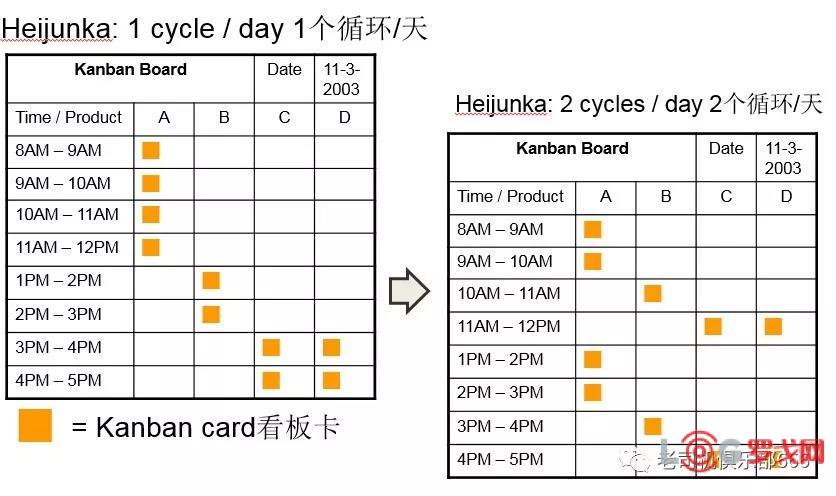

Levelled Production (Heijunka) (平化)

生する物(れにびついた物)のと量を平均化することをいう。ジャストインタイムに生するための前提條件である。

確保生產(chǎn)活動期間零件種類、量、都到均等,JIT式生產(chǎn)的前提。

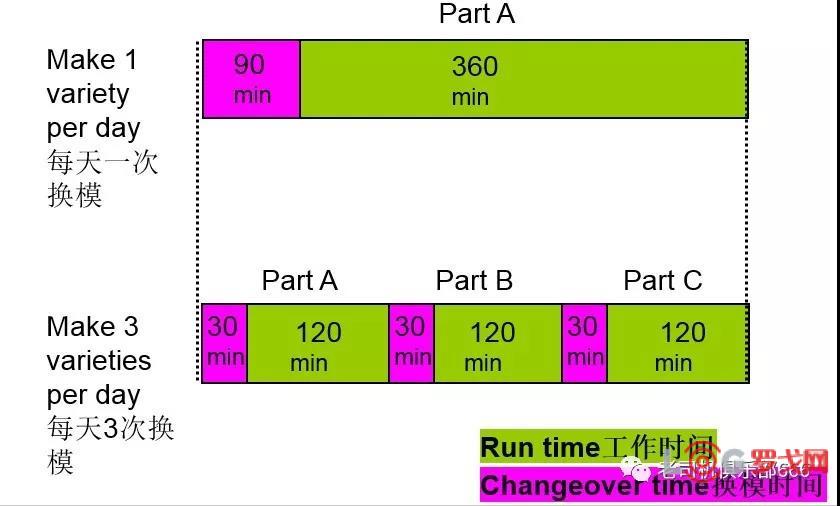

Small lot sizes through quick changeover通過快速換模時間小的生產(chǎn)批量

Information linked to material信息與物料鏈接

Defect-free delivery無缺陷的交付

Attach kanban container看板附在周轉(zhuǎn)箱上

Continuous improvement discipline持續(xù)改進記律

5S discipline 5s紀律

Use kanban to expose and problems 使用看板來暴露問題

Kanban Prerequisite #1: Heijunka看板必要條件 #1

Heijunka = Averaging of both production volume and mix 生產(chǎn)種類及生產(chǎn)量平均化

WITHOUT heijunka, the kanban system will have:沒有均衡化, 看板系統(tǒng)將會:

Excess resources to respond to demand swings,需要多余的資源來應(yīng)對需求的振幅

Excess inventory levels (setting kanban card quantity at maximum demand), or需要多余的庫存(根據(jù)最大的需求來設(shè)置看板卡數(shù)量)

The need to constantly adjust kanban quantities and materials in process up and down to match demand不斷的需要調(diào)整看板數(shù)量及WIP數(shù)量來滿足需求

Kanban Prerequisite #1: Heijunka看板必要條件#2: 均衡化生產(chǎn)

Prerequisite #2: Small Lot Production必要條件#2:小批量生產(chǎn)

Minimize set-up times and other factors that increase lot size

最小化開機時間及其他因素來提高批量大小

WITHOUT small lot sizes, the kanban system will have:

沒有小批量生產(chǎn),看板系統(tǒng)將:

More kanban cards due to long replenishment lead times caused by large batch sizes,因為大的批量造成的補料時間長則需要多的看板

Off-line storage areas for parts not needed in the kanban system (overproduction), and線外的存儲區(qū)域不在看板系統(tǒng)內(nèi)(過量生產(chǎn))

Less responsiveness to downstream changes in customer pull, resulting in more inventory and related waste. 在客戶拉動下游的變化反應(yīng)少,造成更多的庫存及相應(yīng)的浪費

Prerequisite #3: Defect-Free Delivery必要條件 #3: 無缺陷的交付

The container quantity must be correct and defect-free

周轉(zhuǎn)箱中的數(shù)量必須正確且無缺陷

WITHOUT defect-free delivery, the kanban system will have:

如果不能無缺陷的交付,看板系統(tǒng)將會:

A mismatch between the information and the actual materials 實際物料不能滿足信息要求

Shortages when there are defects, or當出現(xiàn)不良時導致缺料

“Just in case” inventory within processes to cover for defects, defeating the purpose of the kanban system.工序的庫存滿足不良,看板系統(tǒng)默認的目的

“Three Don’ts” of Built-in Quality 3個不

Don’t accept poor quality 不接受不良品

Don’t make poor quality 不制造不良品

Don’t ship poor quality 不出貨不良品

This is easy to say, but impossible to do without a supporting system of built in quality.說來容易,但是如有沒有一個支持的質(zhì)量體系是做不到的

Prerequisite #3: Defect-Free Delivery必要條件#3 無缺陷的角度

In-process inspection to guarantee quality過程檢驗來保證質(zhì)量

“Stop and fix” mentality“停下來解決問題”

Root cause countermeasures根本問題對策

Prerequisite #4: Attach Kanban to Containers必要條件#4 看板附在周轉(zhuǎn)箱

Information and materials always travel together信息及實物通常一起移動

WITHOUT kanban attached to containers, the kanban system will have:如果看板沒有附在周裝箱上,則看板系統(tǒng)將會

Mismatches between the information and the actual materials, and信息及實際的物料無法對應(yīng)

Loss of the visual control function of kanban to instruct production or movement of goods.失去了目視化管理的工程來指示產(chǎn)品生產(chǎn)及移動

Prerequisite #5: 6S Discipline必要條件#5 5S 的紀律

Material location, quantity and orientation must be controlled物料的地址,數(shù)量,方向必須被控制

WITHOUT 5S discipline, the kanban system will have:沒有做好5S,看板系統(tǒng)將會:

Shortages due to misplaced materials,物料擺放錯誤造成的缺料。

Delays due to searching for misplaced materials, and因為找料而出現(xiàn)的延誤

Excess materials due to lack of adherence to controls.因沒有嚴格遵守控制而 造成的多余物料

Use Kanban to Expose and Solve Problems必要條件#6 使用看板來曝光及解決問題

Use kanban as a tool for process improvement NOT to hide problems with inventory!使用看板來實現(xiàn)過程改進-不隱藏庫存的問題

WITHOUT exposing and solving problems, the kanban system will have:在不能曝光及結(jié)果問題的情況下,看板系統(tǒng)將會:

Often more inventory in the beginning than without kanban,庫存在最開始的時候經(jīng)常高于未使用看板的時期

Chronic problems that make people want to increase buffers, and慢性的問題造成人們愿意去增加緩沖的庫存

A disconnection with the continuous improvement culture.與持續(xù)改進的文化脫節(jié)。

How to Run the Kanban System 如何來運行看板系統(tǒng)

1、The downstream process withdraws items they need下游工序補充所需要的物料

2、The upstream process makes what is withdrawn上游工序制造所補充的物料

3、The kanban always stays with the material看板要與物料放在一起

4、Wrong or bad materials are never allowed downstream錯誤及壞品不允許流到下游工序

5、Kanban is used only for minor (±10%) adjustments看板僅用于小的調(diào)整 (±10%)

6、Kanban quantities are continuously reduced看板數(shù)量將持續(xù)減少

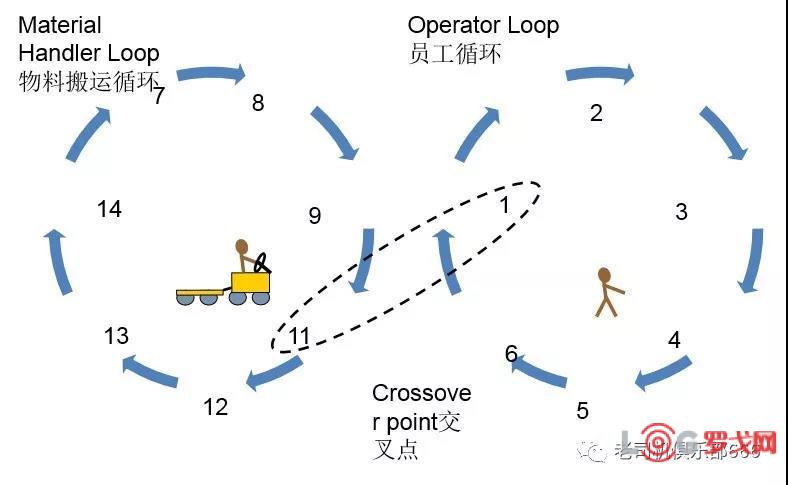

Kanban Circulation Steps看板循環(huán)的步驟

The operator:員工:

1、Receives instruction to produce in the form of production instruction kanban (from step 11)收到生產(chǎn)指示看板來指示生產(chǎn)

2、Takes first piece from raw material (parts) storage area at beginning of line

3、Removes withdrawal kanban card when the first part is taken from container當?shù)谝粋€物料從周轉(zhuǎn)箱取出時取下補料看板卡

4、Places the withdrawal kanban card in the kanban post將補料看板卡放在看板分發(fā)處

5、Place the production instruction kanban in the container of raw material放置生產(chǎn)指示看板到原材料的周轉(zhuǎn)箱中

6、Puts the completed parts with their production instruction cards in the finished goods supermarket將生產(chǎn)完畢的零件與生產(chǎn)指示卡放入成品的超市中

7、When to Pull a Kanban Card?什么時候去拉動一張看板卡

8、Pull the kanban card when the first piece is taken from the container當?shù)谝粋€物料從周轉(zhuǎn)箱周取出時拉動看板卡

9、Keeps the rule simple and consistent保持規(guī)則的簡單及一致性

10、Use the delivery cycle on the kanban itself to specify when the next full container will arrive – not too early當下一個滿箱物料將要到達時使用看板自身的交付循環(huán)來明確說明。

Receives instruction to produce (from step 10)…收到指示進行生產(chǎn)(從工序10)

Key points關(guān)鍵點

Produce only the quantity specified on the production instruction cards僅生產(chǎn)看板指示卡上標識的數(shù)量

Produce in the sequence that the production instruction cards were removed根據(jù)生產(chǎn)指示卡的順序進行生產(chǎn)

The material handler:物料員

Collects withdrawal cards from kanban post after a fixed period of time (if far away) or after a fixed quantity of cards (if nearby)在一個固定的時期從看板架上收集補料卡或者在一個固定的看板數(shù)量后

Transports the withdrawal cards to the upstream process supermarket將這些補料看板卡運送至上游工序的超市

Withdraws the parts and quantities specified on the kanban cards根據(jù)看板卡補充相應(yīng)的零件及數(shù)量

Removes the production instruction cards from the parts containers that were withdrawn當補料時將生產(chǎn)指示看板從物料箱中取出

Places the kanban cards in the production instruction kanban post將看板卡放置到生產(chǎn)指示看板架上

Attach the withdrawal kanban cards to the containers withdrawn將取料看板卡附在物料周轉(zhuǎn)箱上

Transports the parts in their containers with withdrawal kanban cards attached to the downstream process 將附有補料看板卡的物料運送至下游工序

Places parts containers with withdrawal kanbans attached in designated incoming goods store將附有補料看板卡的物料箱放置在設(shè)計好的來料存儲區(qū)域

Key points關(guān)鍵點

Conveyance within the factory is commonly based on a fixed quantity, (variable timing)在工廠內(nèi)運輸通常基于一個固定的數(shù)量(時間可變)

Conveyance between supplier companies and the factory is typically based on a fixed time (variable quantities)在供應(yīng)商及工廠間運輸通常基于一個固定的時間(數(shù)量可變)

Kanban Circulation SOP看板循環(huán)標準作業(yè)

Create standard operating procedure (SOP) documents for team member training創(chuàng)建一個標準的作業(yè)指導來培訓員工

Use visuals使用目視化

Conduct training hands-on手把手

Kanban System Roles and Responsibilities看板系統(tǒng)的規(guī)則及職責

Kanban System Implementation看板系統(tǒng)的實施

Kanban system deployment phases看板系統(tǒng)實施階段

Kanban system design tips看板系統(tǒng)設(shè)計的提示

Kanban implementation pitfalls看板實施的陷阱

Section 5: Kanban System Implementation 看板系統(tǒng)的實施

Kanban System Implementation看板系統(tǒng)的實施

Kanban system deployment phases看板系統(tǒng)實施階段

Kanban system design tips看板系統(tǒng)設(shè)計的提示

Kanban implementation pitfalls看板實施的陷阱

Kanban System Deployment Phases看板系統(tǒng)實施階段

Kanban Systems Design Tips看板系統(tǒng)設(shè)計提示

Packaging包裝

Containers reusable 包裝箱可循環(huán)使用

Pallets purpose-built only 卡板-僅定制

Lot sizes批量大小

Quantity based on pieces (not days’ supply)數(shù)量基于單個(而不是一天的供應(yīng))

Increase or decrease based on demand根據(jù)需求進行增加或減少

Order point訂單點

Placing the signal kanban and material preparation kanban下信號看板及物料準備看板

Quantity-based withdrawal, but timing-based position基于數(shù)量的補料,但是基于時間的位置

Container design周裝箱設(shè)計

Safety first安全第一

Container quantity for signal kanban should be less than one day’s usage信號看板的包裝數(shù)量必須小于1天的用量

Also consider factors such as material presentation to the customer, weight, and space taken at the line也要考慮其他因素例如物料的陳列,重量及生產(chǎn)線需要的空間

Kanban Implementation Pitfalls看板實施的陷阱

Using kanban to manage inventories that should not be there in the first place使用看板來管理庫存不能放在第一位

Connect processes and eliminate through one-piece flow通過單件流來連接工序來消除看板

Setting safety stock and buffers set too high安全庫存及緩沖庫存設(shè)置的太高

2.Having more inventories than when using MRP push比使用MRP相比庫存更高

Attempting kanban for seasonal items在季節(jié)性產(chǎn)品上嘗試看板

Not changing MRP lead-time offsets, such as when batch sizes have been reduced當批量大小減小時沒有變更MRP前置時間的設(shè)置

Using kanban to cover up problems such as machine reliability, scrap or changeovers使用看板來彌補問題例如機器可靠性,報廢或者換模

3.Using both kanban and MRP systems to release material使用看板及MRP來釋放物料

Group Exercises團隊練習

Suggested actions建議的行動

Review value stream maps for areas where kanban are needed查看價值流程圖來發(fā)現(xiàn)需要看板的地方

Calculate kanban quantities 計算看板數(shù)量

Review current state of site against kanban prerequisites查看現(xiàn)狀及看板必要條件進行對比

樂歌股份預計2024年歸母凈利潤下降約50%,大力發(fā)展海外倉

2549 閱讀

前海粵十完成新一輪戰(zhàn)略融資

2503 閱讀

連續(xù)5年的“春節(jié)主力軍”,德邦為何如此穩(wěn)?

1835 閱讀AI改變物流業(yè)的游戲規(guī)則:從炒作到實踐的深度思考

1381 閱讀電商件單票 36元,中國快遞企業(yè)扎堆到中東搞錢

1199 閱讀制造業(yè)企業(yè),不要逼物流公司降價了!

1166 閱讀全球海運市場動態(tài)(一月中旬至一月下旬)

1091 閱讀菜鳥拆分為假消息,繼續(xù)大力發(fā)展全球物流業(yè)務(wù)

1099 閱讀物流行業(yè)如何破“內(nèi)卷”?

1097 閱讀品牌全新升級,牛卡福推出“一站式智慧物流解決方案”,開啟新征程

1025 閱讀